Kuji Sports emphasizes sustainable and eco friendly practices and materials at every stage of the design and production process as well as in the everyday administration of our company

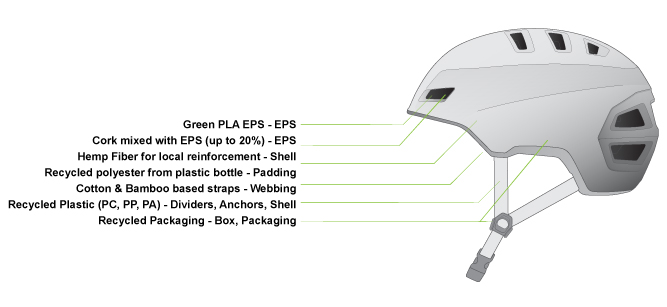

We are continuously looking for Eco friendly materials :

NINGBO TIANQI TECHNOLOGY CO. LTD.

NO.688.HENG SHAN ROAD, ZHEJIANG, 315800 NINGBO, CHINA

TEL: +86.574.8680.2199 FAX: +86.574.8680.2188

网站备案/许可证编号:宁波天旗科技有限公司 浙ICP备12015466号-1

| Cookie | Durée | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by the GDPR cookie consent plugin. The cookie is used to store the user's consent for cookies in the "Analytics" category. |

| cookielawinfo-checbox-functional | 11 months | This cookie is set by the GDPR cookie consent plugin. This cookie is used to store the user's consent for cookies in the "Funcionnal" category. |

| cookielawinfo-checbox-others | 11 months | Defined by the GDPR Cookie Consent plugin, this cookie is used to store the user's consent for cookies in the category "Other. |

| cookielawinfo-checkbox-advertisement | 1 year | Defined by the GDPR Cookie Consent plugin, this cookie is used to store the user's consent for cookies in the "Advertising" category. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR cookie consent plugin. It is used to store the user's consent for cookies in the "Necessary" category. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR cookie consent plugin. This cookie is used to store the user's consent for cookies in the "Performance" category. |

| CookieLawInfoConsent | session | Stores the default button state of the corresponding category and the CCPA state. It only works in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or modify the website content in real time. |

| viewed_cookie_policy | 11 months | This cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not the user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Durée | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session, and campaign data and also tracks site usage for the site analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_194058834_1 | session | Defined by Google to distinguish users. |

| _gid | 1 day | Set by Google Analytics, the _gid cookie stores information about how visitors use a website, while creating an analytical report of the site's performance. The data collected includes the number of visitors, where they come from, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie through embedded youtube videos and records anonymous statistical data. |

| Cookie | Durée | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | The YSC cookie is set by Youtube and is used to track the views of videos embedded in Youtube pages. |

| yt.innertube::nextId | never | This cookie, set by YouTube, records a unique ID to store data about the YouTube videos the user has viewed. |

| yt.innertube::requests | never | This cookie, set by YouTube, records a unique ID to store data about the YouTube videos the user has viewed. |